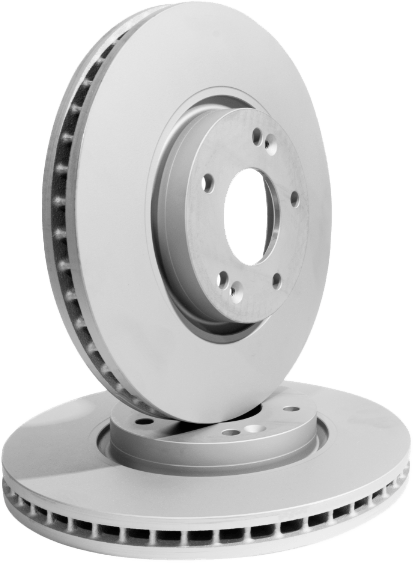

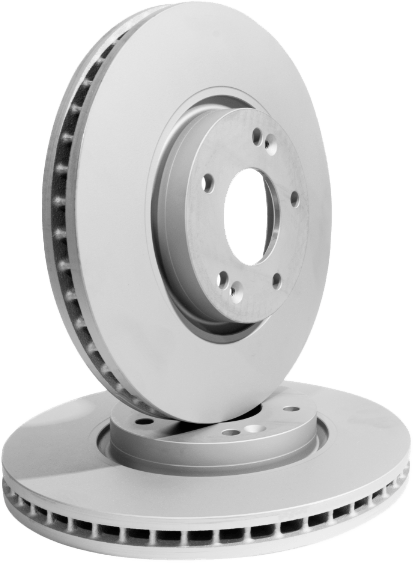

MPA brake rotors are engineered and manufactured to meet or exceed OE specifications for performance and durability.

MPA brake rotors are engineered to meet or exceed OE specifications for stopping performance, durability and quality. Each MPA brake rotor is built to last in state-of-the-art manufacturing facilities and feature G11H18 metallurgy for superior thermal dissipation capabilities and reduced noise across a wide temperature range. Installation-ready, double disc ground rotor friction surfaces reduce promote efficient pad-rotor bed-in and further reduce noise under braking.

Quality Enhancements

Original Equipment Fit and Function

-

Application-specific rotors are engineered and manufactured to meet or exceed OE specifications for stopping performance, durability and quality.

OE Equivalent Castings, Materials and Processes

-

OE style castings and G11H18 metallurgy ensures efficient thermal dissipation, preventing brake fade and thermal fatigue issues.

Installation-Ready Performance

- Double disc ground rotor finishes ensure parallelism, eliminating DTV issues and promoting efficient pad-rotor bed-in.

Smooth Operation

- All MPA Brake Rotors are inspected for balance imperfections and adjusted back to specification preventing vibration and promoting confident smooth stopping.

100% Multi-Stage Tested and Inspected

- All MPA brake rotors are 100% inspected, our quality standards ensure performance right out of the box.